BY JANE MCLAUGHLIN ANDERSON

PHOTOS BY CHRISTINE PETKOV

The U.S. Census predicts that the world population will grow to more than nine million people by 2050. To keep up with the growing demand for food with fewer farmers and shrinking farmland acreage, it is estimated that agricultural production will need to double in the ensuing years. Smart farming is not only a good idea; it is imperative. Precision agriculture is the answer to become more efficient, productive, sustainable and affordable to both producers and consumers. Technological advances continue to evolve in agriculture, from fertilizer and irrigation systems, soil mapping and more efficient farm machinery, GPS systems and programmable tractors, to drones and genetic seed engineering. Necessity is the mother of innovation.

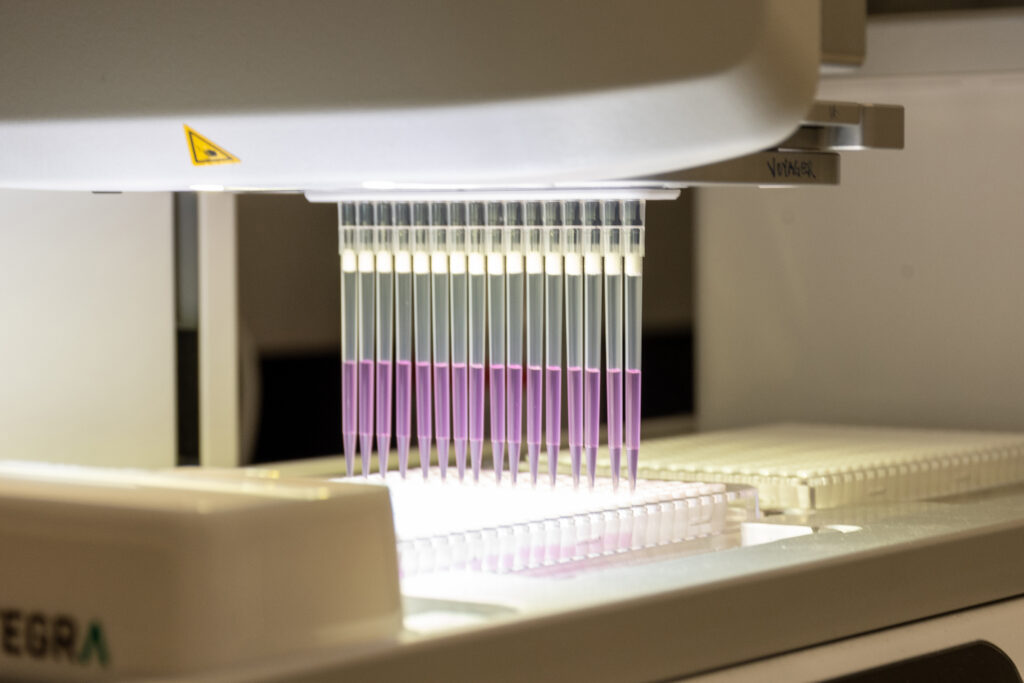

Inari is a privately held company founded in 2016 by Flagship Pioneering, a life sciences innovation firm. Headquartered outside of Boston in Cambridge, Massachusetts, Inari’s goal is to use genetic technology and computational tools to generate step-change products for independent seed companies and, ultimately, farmers. Its business is to provide the best parent seed through gene editing to independent seed companies who, in turn, can create hybrids or varieties for farmers. Inari’s product development center of excellence at the Purdue Research Park was established in November of 2018 and is the world’s first Seed Foundry.

Gene editing is different from genetically modified organisms (GMOs) in that it does not necessarily introduce foreign genes into the seed. Targeted gene editing using the diversity of a plant species’ genome can enable farmers to select specific crop varieties that have features to enhance production.

Since agriculture is a critical industry, Inari continued working during COVID-19. It made recommended social distancing accommodations in labs and the office, but research and development continued. “If anything, COVID-19 reinforced the need for more products to feed the world; products which are better for the environment in terms of being more efficient in their water or fertilizer intake,” says CEO Ponsi Trivisvavet. “We are fortunate to serve during this period of time.”

“Our seed foundry approach is unique to Inari,” Trivisvavet says. “We start with a computational algorithm to gain genetic knowledge. The second step is gene-editing, and the third step is creating the parent seed that we will provide to independent seed companies. The deep knowledge from the very start gives us a continuous feedback loop from the lab and greenhouse to the field. Together with advanced genomic tools, this allows us to cut down the development time by 70 percent, and the economic costs down 90 percent.”

This process shortens the time for product development by about two-thirds as compared to traditional breeding products that can take about 10 years to commercialize, saving both time and money. The goal is to give independent seed companies, and ultimately farmers, a way to maximize yield and profit with products that are friendlier to the environment by designing them to be less dependent on fertilizer and water.

Inari’s expansion to the Midwest was intentional to be closer to the corn and soybean belt. It did a broad search and ultimately chose West Lafayette because of its proximity to Purdue University regarding collaborations with other scientists, technology groups and talent pools. Inari started with 26,000 square feet of space and in one year increased its footprint to about 80,000 square feet, with a greenhouse at Purdue Research Park, plus 80 acres of prime farmland in West Lafayette with two additional greenhouses. Corn, soybeans and wheat are the focus now, with other crops within its sights in the future.

Hoosiers may not realize that these staple crops provide products that are essential for everyday life, way beyond corn syrup, tofu and bread. Components within the corn plant are found in baby food, beer, bricks, cleansers, coated aspirin, cosmetics, diapers, gas and oil, glues, hand soap, jelly beans, matches, paint and varnish, pharmaceuticals, toothpaste, tires, Windex and whiskey.

Soybean components are found in AstroTurf, paintballs, candles, chewing gum, crayons (1 acre of soybeans can produce 82,368 crayons!), fire logs, ink and wood stain. Wheat components are found in adhesives, beer, cosmetics, hair conditioners, liquid laundry detergents, moisturizers, paper and particle board. Life in America depends on these versatile plants.

The whole process begins in Cambridge with computerized models of the plant’s genetic code. Through computational design, it can go through generations of breeding in minutes. Through technology, it can make changes in the genome. What started on the computer is then created in the lab, then taken to the field for more testing and research. The West Lafayette facility specializes in making precise changes in the plant genome in the lab and regenerating those plants to test in the field. Information is continuously fed back into the process to inform the best changes to make the plant exhibit the desired characteristics that are valuable to farmers. This method significantly speeds up the traditional plant breeding process because farmers don’t have to wait a season to gain knowledge.

Inari has a third facility in Ghent, Belgium, that specializes in plant research. It is closely affiliated with Ghent University and the VIB life sciences research institute. Altogether, the company employs 160 people. The West Lafayette location has 70 employees and anticipates hiring more in the next three to five years. Inari is a female-friendly company with a female CEO, Trivisvavet, and a balanced leadership team.

“We are grateful to Purdue President Mitch Daniels and Dean of Agriculture Karen Plaut for their support,” Trivisvavet says. “They have been very helpful, as has the entire community.” Inari hosts Purdue graduate courses for tours and career discussions and science-focused open houses at one of its Purdue Research Park facilities. On their own time, several Inari employees go to local schools to share science and technology with kindergarteners through high schoolers. Inari’s goal is not just to occupy space in the region but also to be an integrated, contributing part of the community.

“I am very excited about the Inari employees in West Lafayette, their experience, commitment and desire to make an impact in agriculture,” says Trivisvavet. “I’m extremely encouraged by the positive people committed to the company, the industry, and the community.”