BY KAT BRAZ

PHOTOS PROVIDED

Embodying an industrious spirit and incorporating advanced technology, small manufacturers contribute significantly to Greater Lafayette’s economic vitality and workforce identity. With an emphasis on innovation, adaptability and craftsmanship, small manufacturers represent a spirit of ingenuity, entrepreneurship and resilience. Here are some of the businesses contributing to the region’s economic growth and promoting a sense of community pride that extends far beyond their workshop floors.

Antique Candle Co. | antiquecandleco.com

Founder Brittany Whitenack took a leap of faith when she left a demanding job, unsure of where life would lead her next. Searching for a creative outlet, she began making candles in her kitchen and gifting them to family and friends. In 2014, she started Antique Candle Co., armed with a business plan and $200 worth of supplies. Over the past decade, the company has grown to a nationally known maker of vintage-inspired artisan soy candles available online and in stores across the U.S. and Canada. From her kitchen stovetop to a 10,000-square-foot facility in Lafayette’s north end staffed with 50 employees, Whitenack remains committed to producing quality hand-poured candles and creating a positive work culture for the Antique Candle Co. crew. In 2022, the company ranked No. 20 on Fortune’s list of Best Workplaces in Manufacturing and Production (Small and Medium).

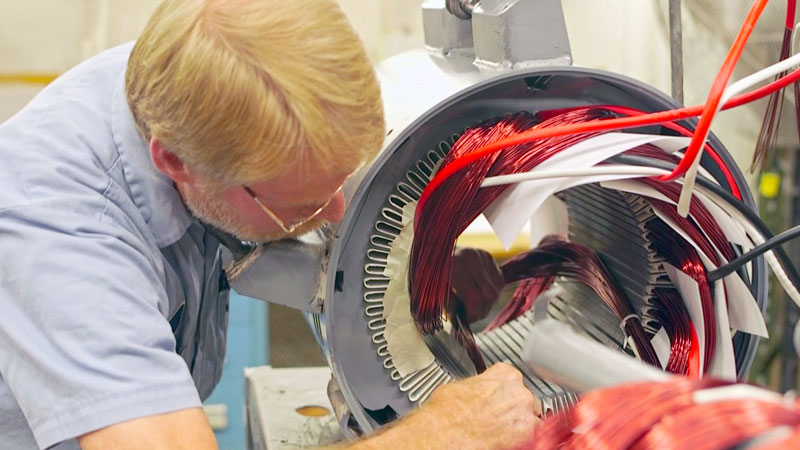

Industrial Plating | industrialplatinginc.com

When Bill Uerkwitz started Industrial Plating in 1955, the metal finishing industry was undergoing a boom. Although the process of electroplating — using electricity to deposit a thin layer of metal onto a base metal object — was first developed by Italian chemist Luigi Valetino Brugnatelli in 1805, the introduction of chemical processes in the mid-1900s led to a surge of electroplating facilities around the country. In response to the global push to reduce the use of environmentally unsafe practices, the industry has become more heavily regulated, and many facilities have closed. Industrial Plating continues to thrive, thanks to the installation of a state-of-the-art waste treatment system and adoption of efficient commercial plating technologies. Industrial Plating’s facility houses nickel, tin, zinc, silver and copper lines. The family-owned business spans three generations with Bill’s son, Darrell Uerkwitz, serving as president for more than 20 years. Once Darrell retires, his daughter, Angela Uerkwitz-Gibson, currently executive vice president, will take charge.

Kirby Risk | kirbyrisk.com

Established as the Keiffer-Risk Battery Company in 1926 in an old blacksmith shop on N. Second Street in Lafayette, Kirby Risk Corporation now encompasses six distinct business operations with more than 40 locations throughout Indiana, Illinois, Ohio and Georgia. A well-respected name in electrical supply and manufacturing, Kirby Risk Corporation remains committed to the concept of sacrificial service embraced by its founder, J. Kirby Risk, and carried on by his son Jim Risk, now chief executive officer. The company also strives to create an environment for employees that encourages both personal and professional growth. It is consistently named as a Top Workplaces winner by the Indianapolis Star. The Risk Family Foundation supports many local organizations, including Junior Achievement and encourages community volunteering across its workforce. The company has shown a long-standing commitment to Greater Lafayette Commerce, United Way of Greater Lafayette and the Greater Lafayette Community Foundation.

Lafayette Instrument | lafayetteinstrument.com

The world’s leading manufacturer of polygraph instrumentation and equipment, Lafayette Instrument also makes scientific instruments for the life sciences and human evaluation industries. It’s also the sole distributor of the Clegg Impact Soil Tester used before every NFL game. The company celebrated its 75th anniversary in 2022 and welcomed a new CEO, Benjamin Mangrich. In April, Lafayette Instrument announced the acquisition of Aurora Scientific, an Ontario-based scientific instrument manufacturer. As a result of the acquisition, Lafayette Instrument expanded its scientific instrumentation line of products providing world-leading academic institutions with the most innovative and high-performance solutions and services in the industry.

SDI Innovations | sdiinnovations.com

SDI Innovations is the engine behind multiple companies and brands. With educational products in more than 30,000 schools and a reputation as the go-to company for agricultural genetic and chemical compliance, the company constantly evolves to uncover the next great innovation. STEM Education Works, a division of SDI Innovations, provides standards-aligned STEM curricula to cultivate the technical competencies and employability skills necessary for student success within regional workforce ecosystems. The company started as School Datebooks in 1985 at Sharon Powers’ kitchen table, which is something company president Tim Powers never forgets. SDI Innovations thrives on a corporate culture centered on “kitchen table values,” including positivity, family spirit, resourcefulness, driving change, comfortable innovation and always doing what’s right.

Steiner Enterprises | steineronline.com

Billed as a one-stop shop for all your original equipment manufacturing (OEM) needs, Steiner Enterprises can make pretty much anything a client can dream up. With more than 25 years in business, the company holds fast to its streamlined production model, which allows for a flexible and customized approach to every project. The company was built on a founding principle of finding a better way to source the right components from the right manufacturers to develop the right product. Its vast network comprises expert local and Far East partners that specialize in a wide range of skills, including mold tooling, injection molding, sheet metal, fabrication, machining, plating, finishing and CNC and Swiss machining. From assessment, design and prototyping to final assembly, product testing and quality control to packaging, shipping and logistics, Steiner Enterprises helps its clients get quality products into customers’ hands safely, efficiently and cost-effectively.

Oscar Winski Company | oscarwinski.com

Oscar Winski, a Polish immigrant who sailed to the United States on a 17-day steerage boat, was inspired to start a scrap metal company while walking the beat as a reserve policeman in Lafayette circa 1900. Noticing the amount of scrap metal generated by businesses and homes throughout the city, Winski spent his off-duty hours pushing a cart around town to collect all the scrap metal he could find. He sorted it by alloy in his garage and sold the material by the truckload to regional mills and foundries. Nearly 125 years and five generations later, the family business has transitioned from a successful metals recycling business to a vertically integrated diversified metals company. Lafayette Steel and Aluminum, a division of Oscar Winski Company, supplies steel and aluminum sheets, coils, plates and structural tubing as well as fabrication services. The company’s success is rooted in the belief that people matter most, and doing the right thing has its rewards. ★